I had time challenges this week along with difficulties getting the MDX-40A set with Fab Modules for cutting wax. I ran out of time fabricating my mold design so I will post that next week.

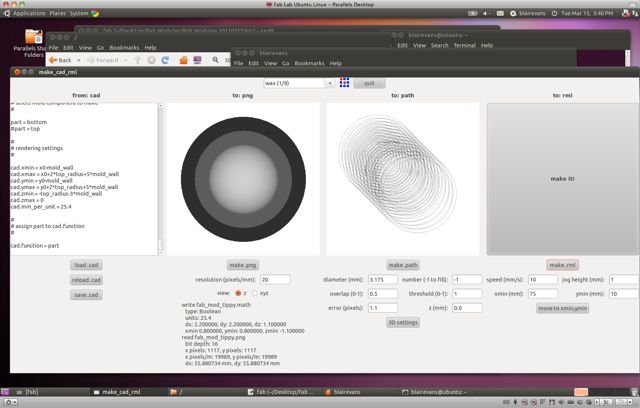

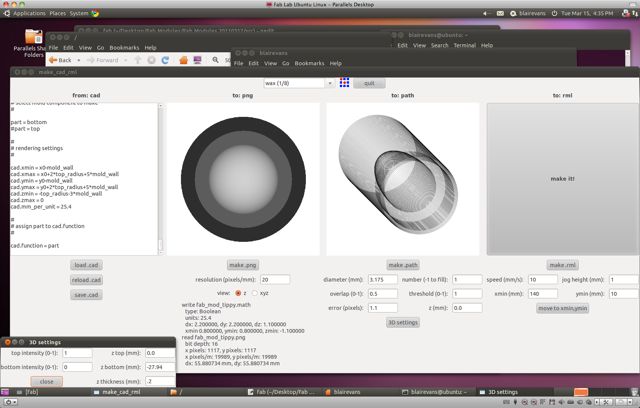

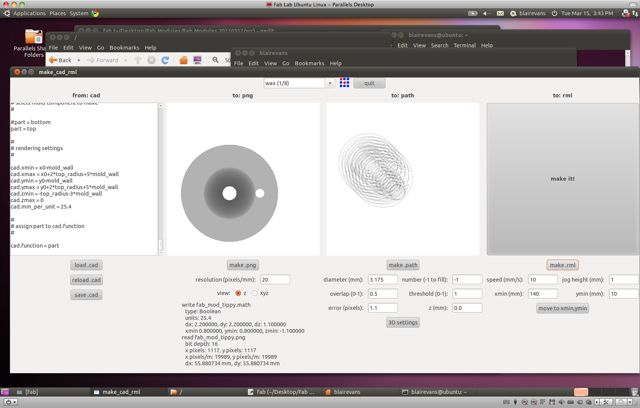

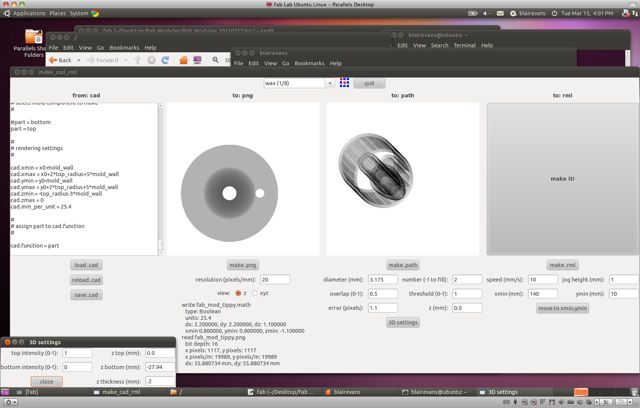

This week I used fab modules to make "tippy" - an existing mold design. This allowed me to debug the process with my mill and get experience with the fabricating process. tippy .cad file

Used Fab Modules to produce coarse and fine rml tool paths for 1/8" ball mill. The coarse paths used 2 mm slices and the fine paths use 0.2 mm slices.

I transfered the rml files to Windows and used the Roland virtual control panel (VPanel) to manage the setup of the cutting. I will have to add some code to setup additional MDX-40A parameters to use fab modules directly, should finish that by next week.

Cut molds for bottom and top out of purple machinable wax.

Used Smooth-On OOMOO 25 for Silicon molds (didn't trim excess silicon).

Used Smooth-Cast 326 for the actual top itself and cured it for an hour at 150 Deg F.

During the first attempt I squeezed the soft mold and moved the mold faces out of alignment producing a defective part.

The next attempt was more seccessful with attention paid to not distorting the mold.

Snapshot of the two tops in action.

An original mold design, the resulting molds and parts plus direct opertion of MDX-40A from fab modules coming soon...